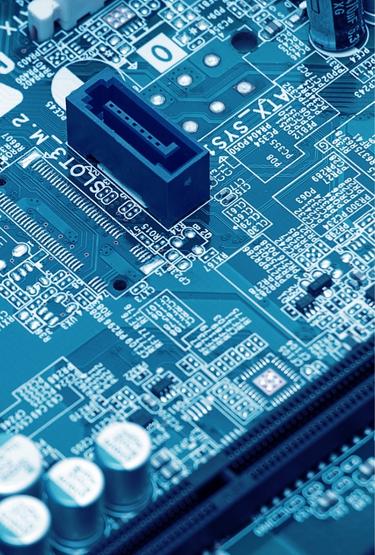

We provide integrated manufacturing collaboration solutions for photoelectric backlight modules, module assembly, and touch industries, and provide comprehensive intelligent manufacturing solutions for the characteristics of short product life cycle, complex process, etc.

Learn More →